10/02/2025

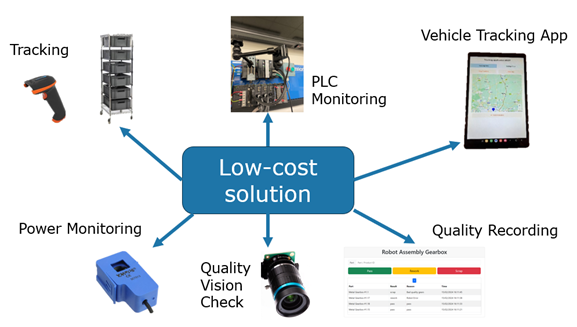

“We noticed a problem early on: we needed to collect data on operations, but we had no software and little IT infrastructure in place. Low-cost Shoestring solutions provided a fast, cost-effective method of adding data collection to the demonstrator factories.”

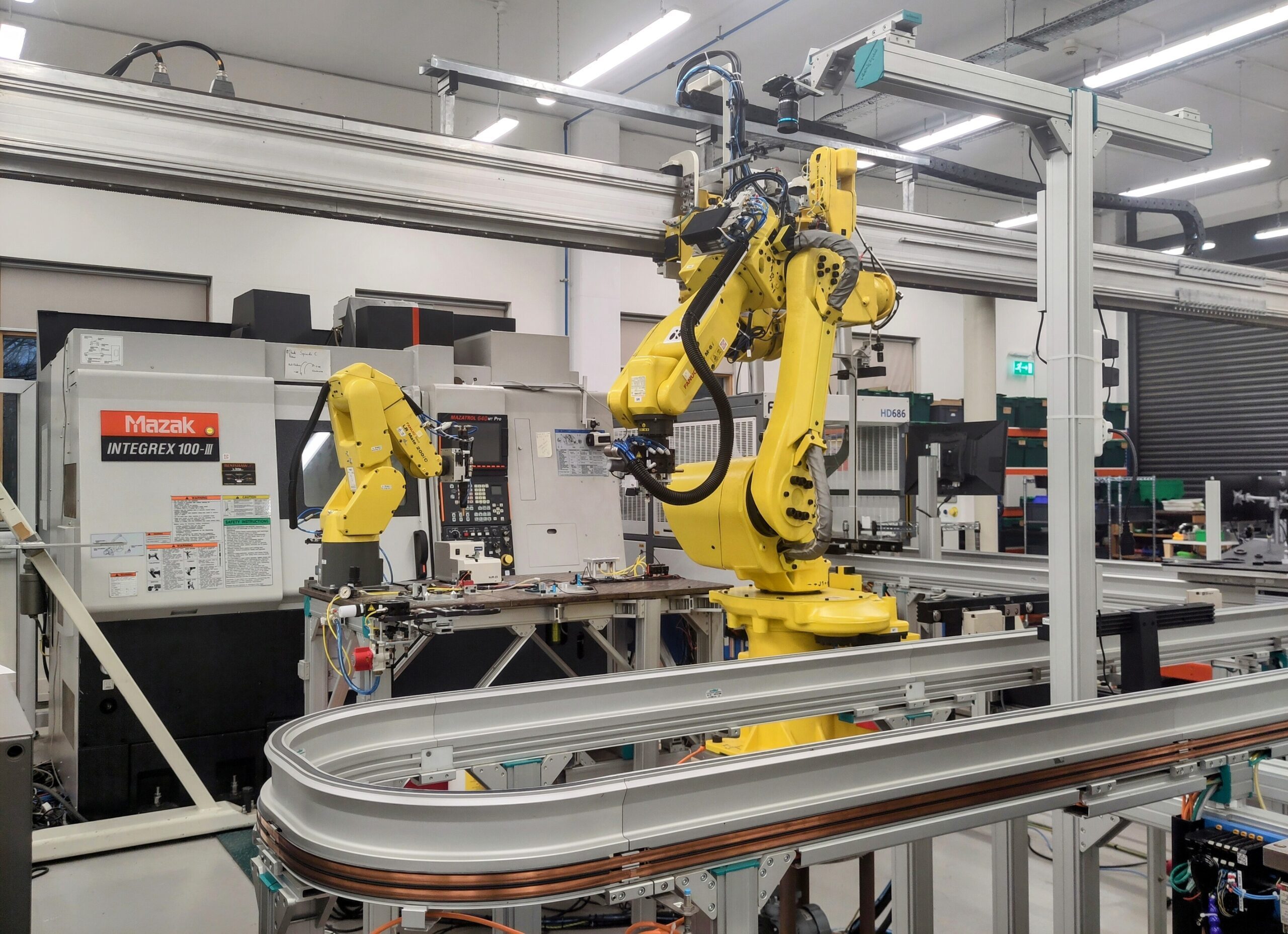

The data collected provided insights on utilisations, production costs, the efficiency of operations and throughput – foundational data needed to inform the overall research vision of developing a new approach to building the manufacturing infrastructure of the future.

The Starter Solutions used from Shoestring include:

- Power Monitoring – Monitoring power use by machines provided data for estimates of production costs and machine utilisation.

- Location Tracking – Product and order status and location were easily identified to save time when searching for products. Data can also be analysed to identify throughput or bottlenecks.

- Scrap Monitoring – Product errors and causes were recorded on tablets and used to identify sources of waste.

Several new low-cost solutions were created during the project:

- Non-invasive PLC monitoring – a camera records programmable logic controllers (PLC) states on legacy machines without connectivity.

- Transport Vehicle Tracking – vehicles with orders are tracked between factory sites using low-cost tablets with SIM cards.

- Composition Tracking – objects like material, parts and orders are linked together to provide traceability of material or parts used in each order.

These solutions were combined with other open-source software to manage and schedule operations. The long-term aim is to offer these new solutions created as part of Shoestring | Digital Manufacturing. For more information about the research project and the outputs, contact the lead researcher, Dr Sam Brooks.

Find out about the project’s technical outputs and case studies on the project website at https://www.connectedfactories.org/

If you are interested in finding out how your company or organisation can get involved in the Shoestring programme, or would like to know more, we would love to hear from you!

Please email us at: contact@digitalshoestring.net

The Made Smarter Connected Factories Centre is a collaboration between the University of Cambridge, the University of Nottingham, the University of Sheffield, and the Advanced Manufacturing Research Centre (AMRC), funded by EPSRC and the Made Smarter challenge. The Cambridge research is led by the Distributed Information and Automation Laboratory (DIAL), register for the newsletter to keep up-to-date with their latest research.