Scrap monitoring

Reduce waste with real-time visibility of the reasons why parts or products are scrapped.

Shoestring’s scrap monitoring solution gives companies an easy way to get started and see how digitalisation benefits their business, building in-house digital skills along the way.

Solve time-consuming problems

Quickly get answers to questions such as:

How much scrap is produced?

Which parts/products or operations have higher scrap rates?

What are the most frequent reasons for scrap across production?

Is our scrap control improving?

The benefits

Shoestring’s scrap monitoring solution allows you to:

Produce more good parts

Quickly identify and address problems

Improve stock planning accuracy

How the solution works

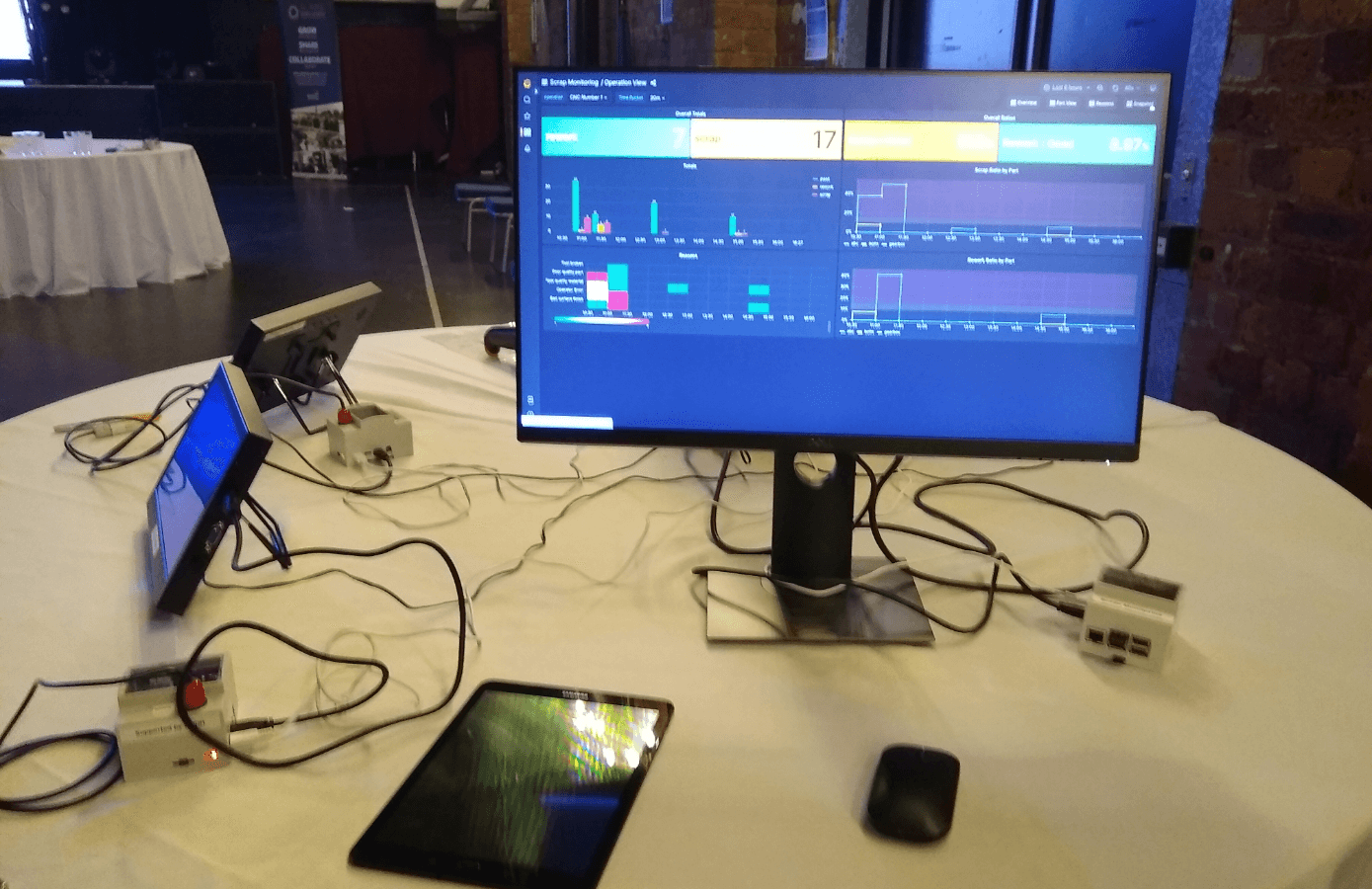

Update the status of scrap via an app loaded on a tablet, computer or phone. Staff can then see the status in real-time on a dashboard, download the data and analyse trends.

How to set up the solution

Scrap monitoring is simple to set up and use. Here’s how:

- Use an app on a tablet, phone or computer to update the scrap status

- Define the work you are doing and whether you are handling a single part or a batch of parts

- Input the part number and whether it passes, needs a rework, or is scrap

- Add a reason for your choices

- Dashboards show scrap and rework by operation and part/product

COMING SOON Case study:

Scrap monitoring at Denchi

By partnering with Shoestring, Denchi implemented a cost-effective job tracking system, transforming their operations with real-time visibility and enhanced decision-making capabilities

In the meantime please take a look at some of our other case studies.

Choose another solution

Job

location tracking

Read more

Improves productivity with real-time visibility of jobs on the shop floor.

Downtime

monitoring

Read more

Keeps track of machinery utilisation with real-time visibility of the reasons behind downtime.

Air quality

monitoring

Read more

Keeps track of the air quality of a factory or office space. This can be used to help maintain healthy and comfortable work conditions.