Temperature monitoring

Keep track of the temperature of a space or process in a factory or office.

Shoestring’s temperature monitoring solution gives companies an easy way to get started and see how digitalisation benefits their business, building in-house digital skills along the way. The package includes a 6–8-week training programme, topped and tailed with a workshop, with weekly catch-up meetings and proactive feedback in between. The starter solution is designed to provide a practical learning experience.

Solve time-consuming problems

Quickly get answers to questions such as:

How hot is this process getting?

What is the optimum temperature for this operation?

When does this temperature exceed safe limits?

The benefits

Shoestring’s temperature monitoring solution allows you to:

Optimise production processes

Stay on top of quality control of materials and components

What’s needed from you?

A solution champion

Someone who will champion the solution deployment and make sure it gets the time and attention needed to make it a success (this person will get hands-on experience leading a digital project).

A solution implementer

Someone who will do what is needed to get the solution deployed (this person will develop practical digital skills – the only prerequisite is being interested).

How long does it take?

To deploy

The solution can be deployed in an afternoon once everything is ready. For most companies it takes 1-4 weeks to get everything ready (purchase the components, coordinate with their IT support, and set aside time for the implementer).

To use and review

4+ weeks: Once deployed, companies use the solution day-to-day for at least 4 weeks before we meet to review what has been learnt and what the next steps could be.

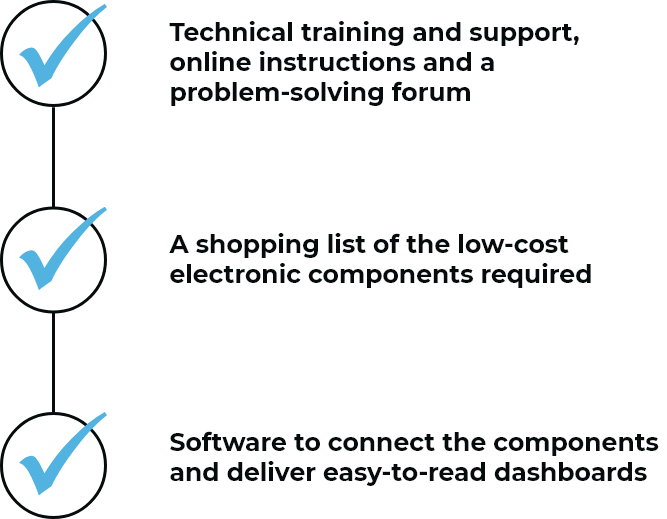

What you get:

How the solution works

Measure the ambient temperature of a space or process in your factory, we will advise you on which sensor is suitable for what you want to monitor (contact, air or infrared).

How to set up the solution

Temperature monitoring is simple to set up and use. Here’s how:

- Use the simple to follow guide for installing the sensor

- Data from the sensor transmits to an easy-to-read live dashboard which can be accessed from any device on the same WiFi network

- The dashboard gives access to real-time and historic data

Case study:

Temperature monitoring at Kemdent

Kemdent is a small-sized company that manufactures dental products for the professional dental market worldwide. As a small traditional manufacturer, Kemdent faced challenges in starting their digitalisation journey due to the overwhelming options available.

Choose another solution

Job

location tracking

Read more

Improves productivity with real-time visibility of jobs on the shop floor.

Power

monitoring

Read more

Helps companies understand energy consumption by tracking actual equipment power usage.