Case studies

Discover how Shoestring helps companies save money and improve productivity while their employees learn to harness the potential of low-cost technologies.

Shoestring has interacted with over 450 small-and-medium-sized companies across multiple sectors, predominantly manufacturing, but also construction, logistics and healthcare.

A whole range of organisations, including local authorities, manufacturing groups and educational institutes, in particular further education colleges, have contributed to and support the programme. These case studies illustrate the impact Shoestring is having across the manufacturing sector, and the impact it could potentially have across other sectors.

All case studies

Element Engineering

Humidity and Temperature monitoring

Element Engineering wanted to ensure the components stored for use in PCB’s were kept at the correct temperature and humidity to mitigate degradation and damage.

Element Engineering

Power monitoring

Element Engineering wanted to enable real-time monitoring of power consumption, allowing for analysis of trends and optimisation of machine usage.

Noshing Dairy Free Cheese

Noshing wanted to address their increasing costs and a sensible place to start was to identify which items were the biggest power consumers.

Buchanan Orthotics

Deploying job tracking encouraged staff to seek ways to improve capacity, costing and lead times.

PIL Membranes

With energy costs rising PIL Membranes were keen to start monitoring and optimising the power consumption of their machinery using low-cost technology.

Denchi

Denchi, a battery manufacturer serving commercial customers, sought to improve their production efficiency and address challenges with manual tracking processes.

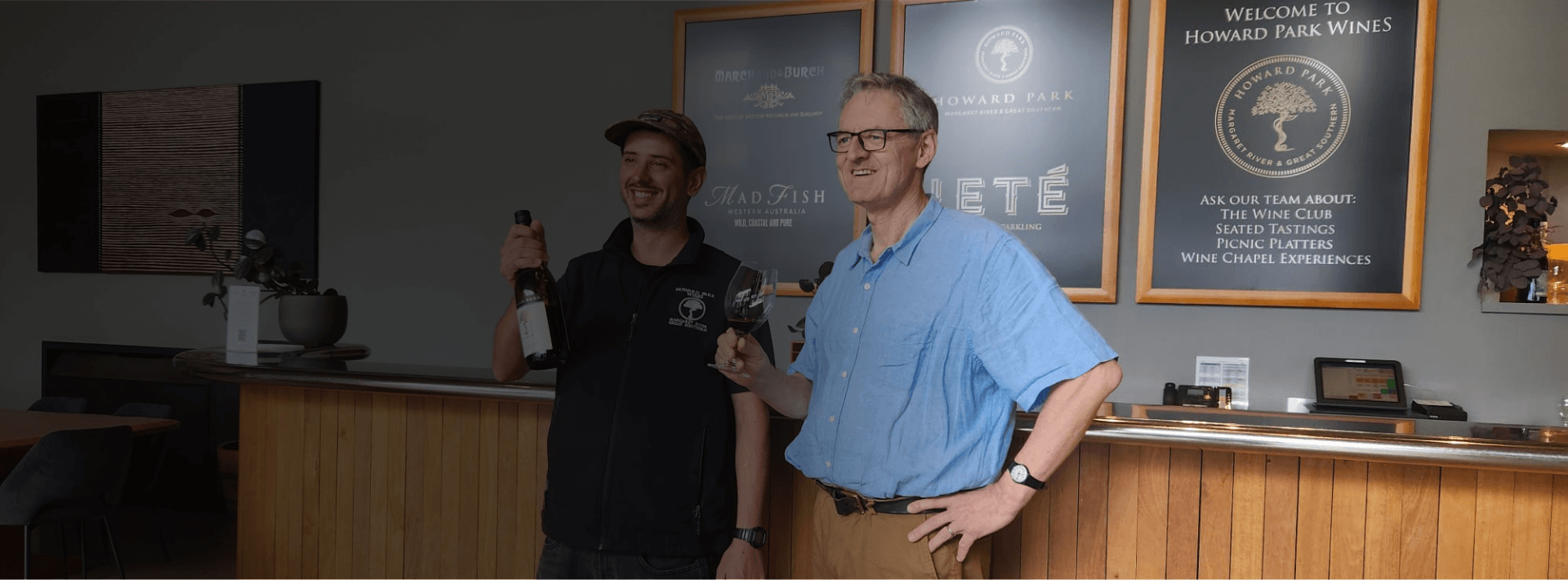

Howard Park Wines

When faced with the challenge of reducing carbon emissions while managing a high-demand production environment, Howard Park Wines turned to Shoestring Digital for practical and cost-effective solutions.

Kemdent

Bewildered by the myriad of options available, Kemdent was unable to find a way to start using digital technologies to drive resource efficiency in their wax forming process, until the team met Shoestring.

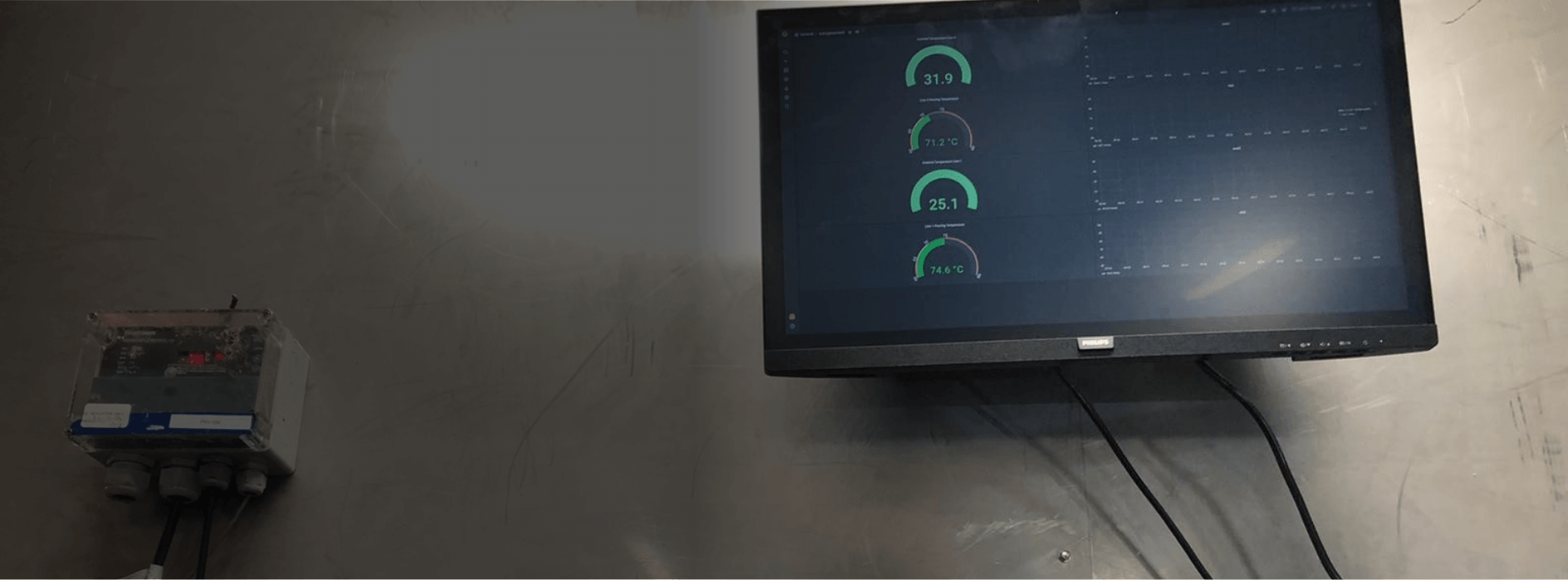

Shelter Brewing Co

Shelter Brewing Co., a brewery located at the foot of the picturesque Busselton Jetty in Western Australia, faced challenges with gaps in their original brewing system – they turned to Shoestring for a solution.